Global SCM (Trading and International Procurement Office)

Global Procurement

Speedy and Stable Procurement through Our Global Supplier Network

Our procurement activities are centrally controlled by utilizing reliability of Sumitomo Corporation to ensure bulk purchasing. Depending the place of origin, costs and lead time, we select the best location for customers’ applications from our partners.

Advantages of Bulk Purchasing

Utilize the purchasing power of Sumitomo Corporation’s credit capability to ensure bulk purchasing.

Overall procurement activities are centrally controlled.

Alternative Proposal

We can propose replacement to a non-Japanese (ex. Taiwanese, Hong Kong, and Chinese) alternatives from our delivery experience for Japanese customers.

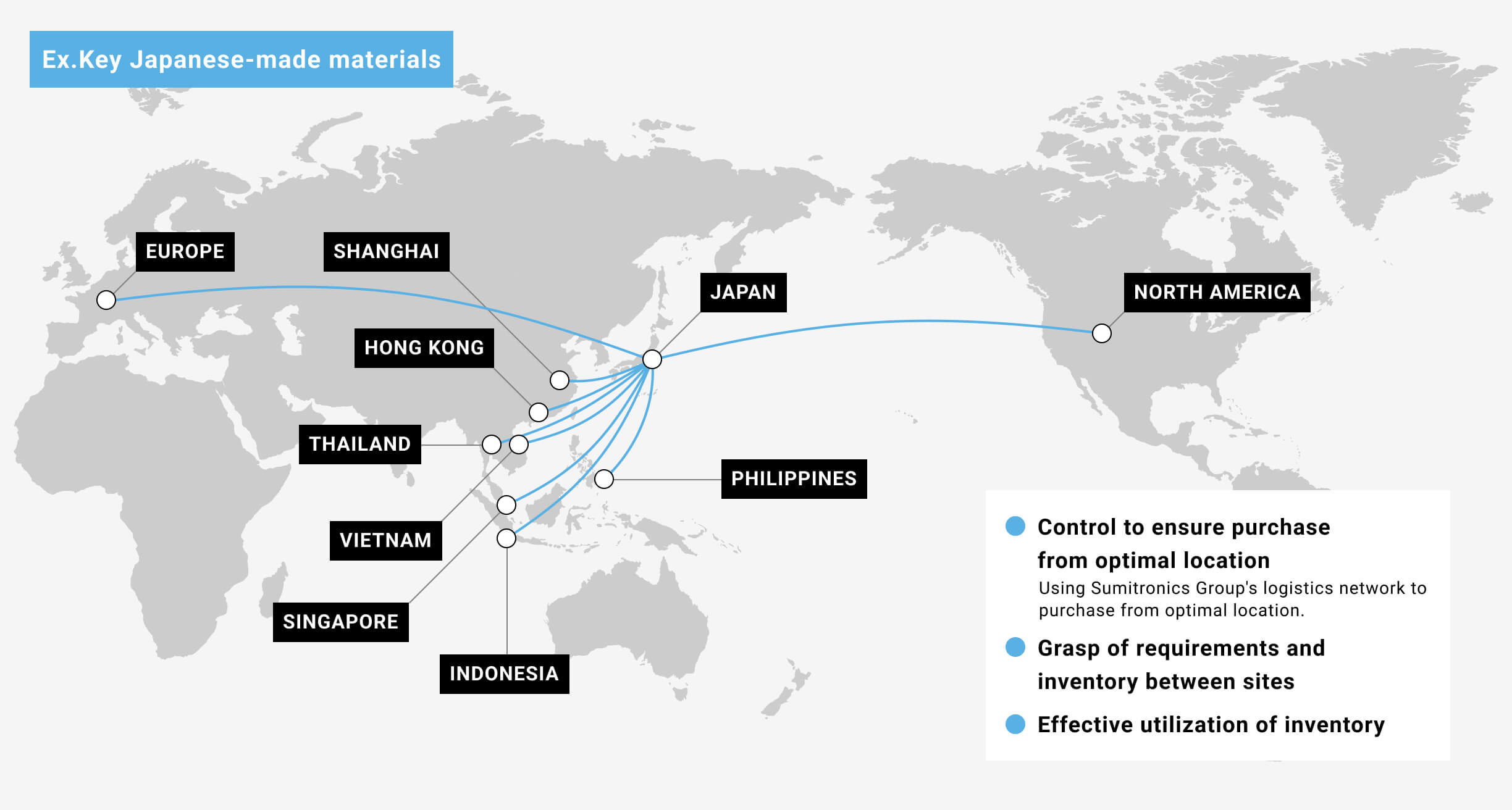

Direct Purchase at the Place of Origin

Purchasing from optimal location per site depending on the place of origin, cost, and lead-time.

For example, we enable to minimize your administration cost, distribution costs and foreign exchange risks by purchasing key Japanese-made materials compare with your procurement by yourself.

Optimized Logistics

Optimized Logistics with Our Network and Warehouse for Electric Components

We are able to achieve low-cost, efficient delivery by utilizing our global network and we collectively transport parts of multiple customers to our overseas. We are also able to reduce inventory and improve cash flow with JIT delivery and warehouse operations.

A Globally Expanding Network

We are able to achieve low-cost, efficient distribution by utilizing our global distribution network and collectively transporting the parts of multiple customers to our overseas sites.

Reduce inventory by utilizing the duty-free/bonded warehouse operations and JIT delivery

We utilize our duty-free/bonded status in our warehouse operations at our overseas sites. We procure electronic parts from our overseas suppliers, import them on duty-free/bonded status, perform incoming inspections, store the parts in a temperature-controlled specialized warehouse, and have them ready for delivery in any quantity at any time for our customers and manufacturing partners. For example, in Thailand we were the first to obtain an IPO license for duty-free importing of electronic parts for re-exporting purposes. The license allows us to reduce the man-hour involved in import customs clearance and duty-free procedures, and store not only PCBA/electronic parts but also mechanical parts on duty-free status and provide JIT delivery of these parts. We also provide VMI operations.

Duty-free/bonded status

| HongKong/Shenzhen | Processing with customers’ materials / Processing with imported materials |

|---|---|

| Shanghai/Suzhou | Waigaoqiao Free Trade Zone (Transit Trade After Processing) |

| Thailand | BOI Duty Free Status for IPO |

| Philippines | PEZA |

| Indonesia | PLB |

| Mexico | Maquiladora |

- Reduce inventory, and minimize storage

- Reduce man-hour involved in import customs clearance

- JIT delivery of not only PCBA/electronic parts, but also various mechanical parts

An added-value logistics design

With a firm grasp of the distribution circumstances and taxation system of each country, we implement a logistics design that best meets the regulations in each country. Moreover, we establish logistics designs which take into consideration tax saving, such as importing on duty-free/bonded status and Value-Added Tax (VAT).

Meticulous support

Detailed Support

Business Support through Comprehensive Strength of Sumitomo Corporation

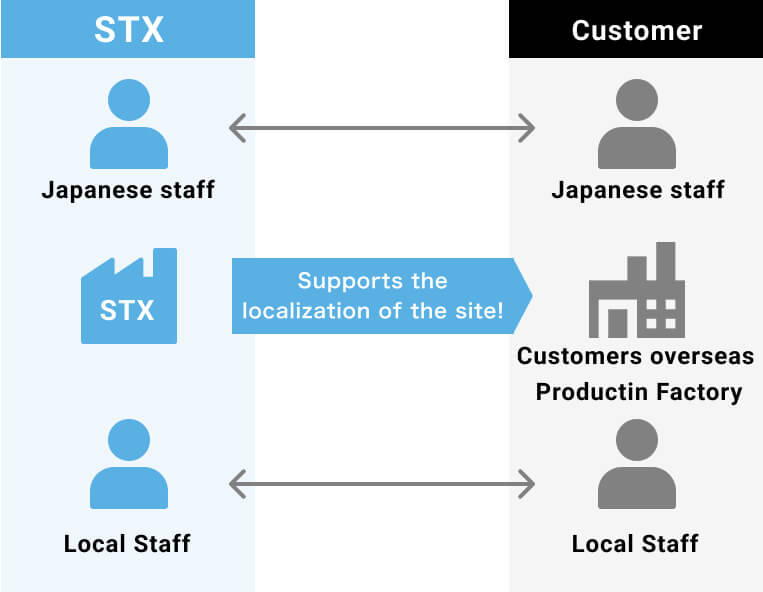

Localization Support

In order to improve the efficiency of overseas production sites, it is necessary to localize, where operation is primarily under local staff. As we continue to develop on a global scale, we provide support for building a business framework most suitable for the location of our customers’ production sites and increasing efficiency.

We provide complete support by having our local expert Japanese staff communicate with our customer’s Japanese staff, as well as having our technical expert local staff communicate with our customer’s local staff.

Improving Customers’ Cash Flow by Trade Finance

The administration of overseas production sites not only involves field operations such as procurement/purchasing and manufacturing, but also treasury operations. We provide support for both field operations and treasury operations such as payment to suppliers, foreign currency exchanges, and overseas remittances.

Comprehensive Support for Overseas Operations

As a member of the Sumitomo Corporation Group, we provide complete support for our customers’ overseas businesses in various cities worldwide. For customers that would like to expand overseas but are concerned about infrastructure, we introduce the overseas industrial complexes that are developed and distributed by the Sumitomo Corporation. We not only provide information, but provide support for establishing a local business, preparing production facilities and materials, and other logistical matters. We are sure that the scope of the kinds of support we provide will exceed your expectation.

Production and Solution

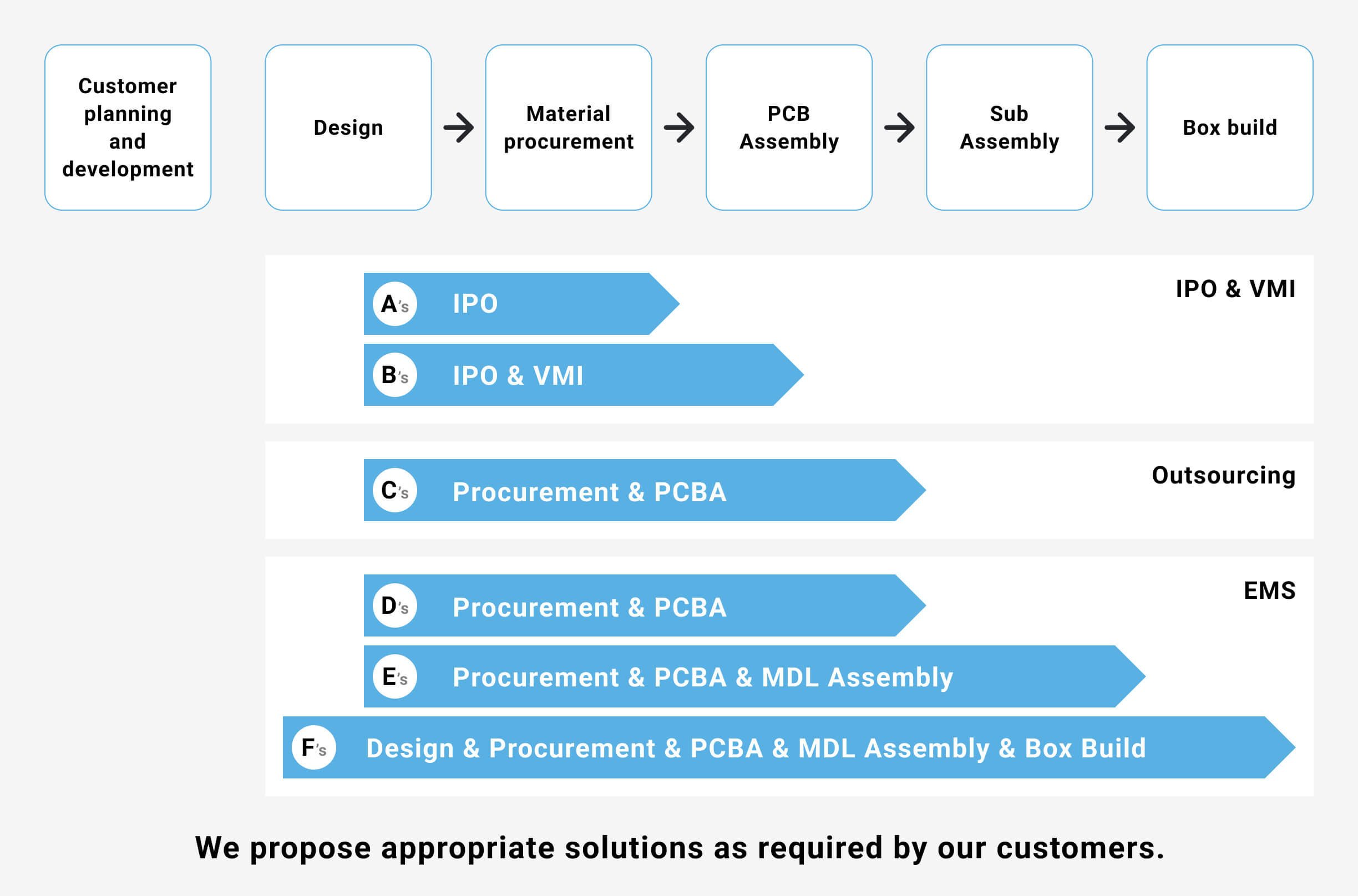

IPO & VMI Business

We sell materials at a low price through our global material procurement capability (optimal location procurement) using Sumitronics’ mass purchasing power. Kitting support for the customers’ production schedule is also available.

Outsourcing Business

Sumitronics faithfully follow your operation by appointing your designated route of procurement and plants.

EMS Business

We realize low prices and high quality at the same time by strategic optimization of material procurement and distribution routes through integrating yours and Sumitronics’, undertaking production at a plant best suited to the application. We provide you wide-ranging support from PCB Assembly, sub assembly and design to finished products.